The Tripor range is our own two-part liquid polyurethane blend.

Here at Trident, we manufacturer from basic raw materials so we are in a unique position to supply to a wide range of customers with bespoke requirements.

As we have a broad range of manufacturing capabilities we can create high-quality end products, bringing your ideas into reality.

We can assist with your project from start to finish, providing information on which of our materials would be best suited for your project, or we can simply supply your material requirements.

Tripor

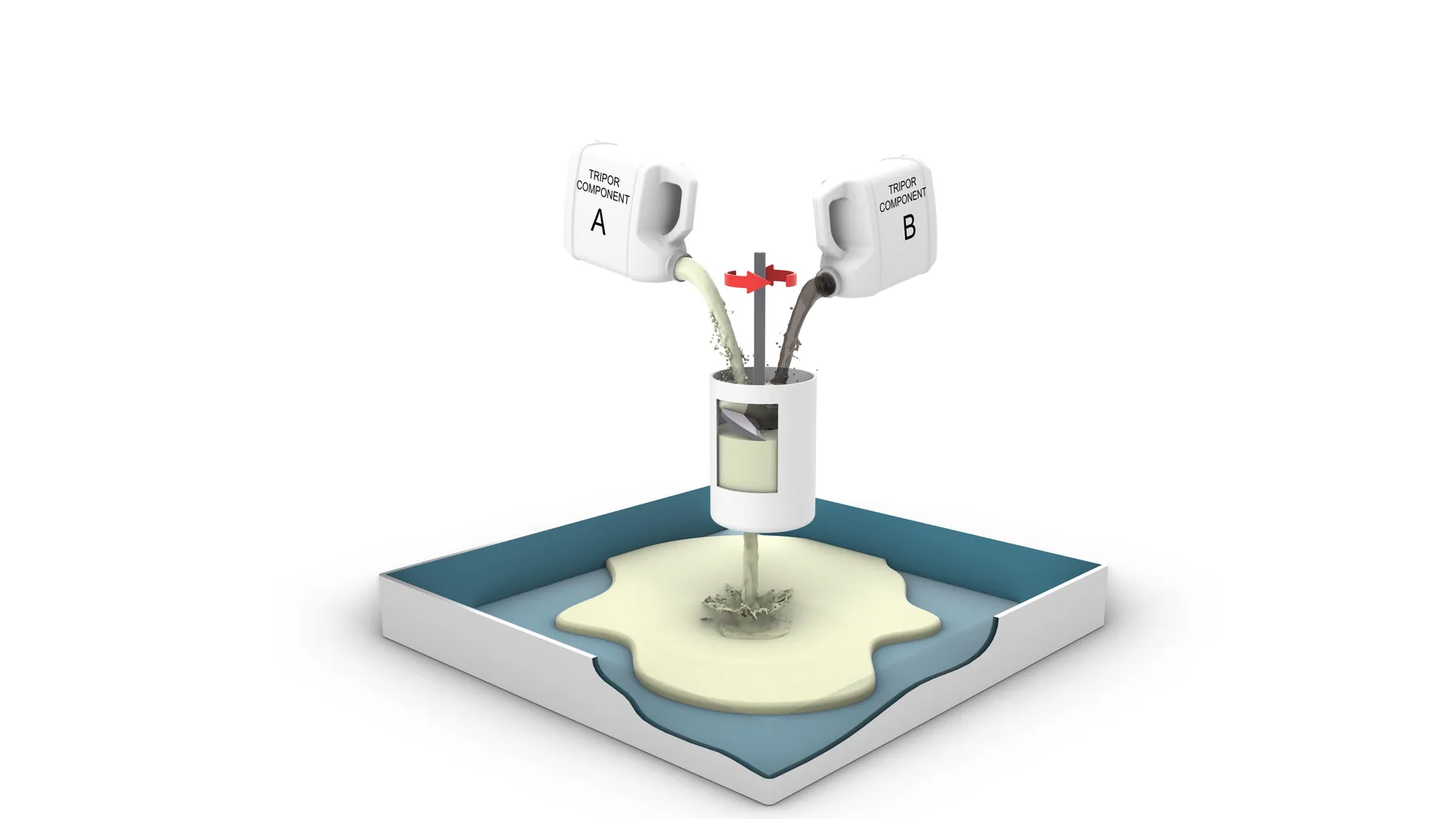

Tripor is our range of a two-part liquid polyurethane foam system, designed for easy use by inexperienced operators with simple tools. Liquid components A and B when mixed, react to form a foam structure.

Supplied in 10kg, 50kg and 450kg packs. The Tripor 200 range contains no chlorofluorocarbons (CFC’s) or halo-chlorofluorocarbons (HCFC’s). Tripor also has an Ozone Depletion Potential (ODP) of zero & very low GWP (Global Warming Potential) with an overall figure of <5 where carbon dioxide is given as 1.

- Lightweight mouldings or castings where applications require a combination of physical strength characteristics and good thermal insulation

- Surface damage, cut errors and pattern changes are easily filled, rectified, and repaired

- Building insulation and refrigeration doors & panels

- Lightweight infill of fiberglass or plastic components

- Filling of large voids where the foams balanced flow behaviour leads to good cell structure and adhesion to a wide range of substrates

* Click the materials tab above to see our Tripor range in detail.

- Tripor 203

- Tripor 204

- Tripor 206

- Tripor 207

- Tripor 216

- Tripor 217

- Tripor 224

- Tripor 226 (Range)

- Tripor 227

- Tripor 227 FR

Tripor 203

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Medium density – 100kg/m3

- Slow reacting

- Rise time = 330-400 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.2 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 204

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Medium density – 110kg/m3

- Fast reacting and better for small castings

- Rise time = 135-155 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.33 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 206

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- High density – 160kg/m3

- Slow reacting, good for large castings

- Rise time = 300-400 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.15 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 207

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Medium/high density – 130kg/m3

- Slow reacting

- Rise time = 300 (from start of mixing till surface can be lightly touched without foam sticking)

- Ratio = 1 : 1.2 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 216

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Medium density – 80kg/m3

- Slow reacting

- Rise time = 400-470 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.2 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 217

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Medium density – 80kg/m3

- Faster reacting version of 216

- Rise time = 170-220 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.2 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 224

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- High density – 200kg/m3

- Slow reacting

- Rise time = 350 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.1 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 226 (Range)

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- High density system (150/220/320/450/550 kg/m3)

- Slow reacting

- Easy mixing 1 : 1 mix ratio (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 227

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Polyurethane (PU)

- Low density – 45kg/m3

- Fast reacting

- Rise time = 180-230 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.2 (by weight)

- Contains no CFC's or HCFC's

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

Tripor 227 FR

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

This variation of Tripor 227 has been specially formulated & contains a high level of fire-retardant additives.

- Polyurethane (PU)

- Low density – 48kg/m3

- Flame Resistant

- Fast reacting

- Rise time = 180-230 seconds (from start of mixing to end of rise)

- Ratio = 1 : 1.2 (by weight)

- ODP of zero

Once cured the final object may be demoulded; if post finishing is required any release agent must be removed from the surface, standard finishes such as paint systems may be used to create a variety of effects. The adhesive properties of liquid foam are significant, this allows the use of metal, plastic, or wooden inserts; it may even be advantageous in panel manufacture when two substrates require bonding together.

- Tripor 203

- Tripor 204

- Tripor 206

- Tripor 207

- Tripor 216

- Tripor 217

- Tripor 224

- Tripor 226 (Range)

- Tripor 227

- Tripor 227 FR

Tripor 203

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Ideal for manufacturing mouldings

- Suitable for structural infill of fibreglass components

- Equivalent to Tricast 6

Tripor 204

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Ideal for manufacturing mouldings

- Suitable for structural infill of fibreglass components

- Similar to Tricast 6

Tripor 206

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Ideal for manufacturing mouldings

- Suitable for structural infill of fibreglass components

- Equivalent to Tancast 10

Tripor 207

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Ideal for manufacturing mouldings

- Suitable for model and pattern-making applications

- Equivalent to Tancast 8

Tripor 216

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Ideal for GRP moulding

- Suitable for semi structural infill of fibreglass components

- Equivalent to Tricast 5

Tripor 217

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Better for smaller castings

- Nearest equivalent Tricast 5

- Suitable for semi structural infill of fibreglass components

Tripor 224

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Suitable for semi structural infill of fibreglass components

- Ideal for larger castings

- Equivalent to Tancast 12

Tripor 226 (Range)

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- 266/220 similar density to Tancast 16

- 226/320 similar density to Tancast 20

Tripor 227

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Nearest equivalent Tricast 3

- Ideal for manufacturing mouldings

- Suitable for structural infill of fibreglass components

- General-purpose infill hand or machine

Tripor 227 FR

Tripor is ideal for use in pouring into moulds and cavities. As it reacts it rises flowing into complex shapes.

- Lightweight mouldings that require a combination of physical strength characteristics and good thermal insulation.

- Building insulation and refrigeration doors & panels.

- Lightweight infill of fibreglass or plastic components.

- Filling of large voids where the foams balanced flow behaviour leads to good cell structure and adhesion to a wide range of substrates such as aluminium and steel.

- GRP manufacturing, including tanks, cabinets, sections and shaping.

Technical & Safety Data Sheets

Tripor 203

Tripor 204

Tripor 206

Tripor 207

Tripor 216

Tripor 217

Tripor 224

Tripor 226 (Range)

Tripor 227

Contact a member of our team for a quote today

Goyt Valley Industrial Estate

Furness Vale, High Peak

SK23 7SN